A fellow steel mill modeler commenting on my blog awhile ago said - "I can't wait to see how you do those uptakes". That was actually my feeling on them too, and the reason that I am just getting around to them now. Trapped in the house for a snowy weekend, it seemed like a good time to start thinking about the upper works of my A-Furnace. Most of the uptake assembly boils down to a lot of pipes connecting at many different angles - but there are two very complicated steps that are part of the assembly - the intersection of the two lower uptakes, and the connection from the furnace body to the uptakes.

The intersection is more complicated than most other scratchbuilt furnaces I have seen. Bethlehem Steel elected to do some real fancy sheetmetal work at this intersection as evidenced by the prototype photo. Besides the weird mess at the intersection, the upper part of the intersection is actually transitioning from one diameter pipe to a larger one, just to make things a bit more interesting. In my model, the lower uptakes are 3/4" Plastruct tubing - this will transition into 7/8" tubing, and then transition to 1/2" for the bleeders. Additionally, more 7/8" pipe with come off the uptake and meet at the 1" downcomer. I've worked out a plan to accomplish all this - it won't be easy, but it should work with a little patience and care in shaping the parts.

The second problem is that, also unlike most model furnaces, the Bethlehem Steel prototype that I am using had uptakes that started to angle back in two segments to the furnace body - above the deck of the charging platform. It is much easier if the cut back starts right at the charging deck. Building it this was allow you to attach the piping and center it up on the deck as you build the upper works. After much thinking I elected to cheat a bit here and deviate from the prototype for the sake of streamline construction. I probably won't be noticeable to anyone that hasn't spent hours studying the Beth Steel A-Furnace plans.

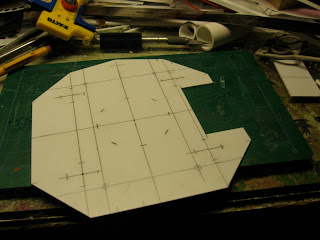

So, the easy work is done - the deck was cut from .040 styrene and 1/8" i beams and square strip were added under. The uptakes were cut from 3/4" tubing and assembled up to the intersection. The next post will take us past there and on up toward the downcomer.

No comments:

Post a Comment